Septic tanks are a fundamental part of the total building construction, without which the building functions will not be optimal.

Septic tanks when well designed, and all parameters put in place, work perfectly well, are cost effective and function much better than bio digestors.

Biodigesters.

Biodigesters are on 2 categories, the 1st category is the one that uses gravity just as a septic tank and the 2nd category is the one that uses an electric air blower. The electric air blower type costs in the range of kes 1m and works perfectly. The only drawback is the steep cost of installation and the high cost of maintenance since it uses electricity daily.

The 1st category of biodigesters usually cost less than the electric ones but slightly more than septic tanks. These are prone to blocakge and failure since their sizes are too small, not commensurate with the daily water consumption of the house, and elements such as grease taps and ample size for the biodigestion to occur is not present, hence failure.

This leaves building owners with 2 options, either the expensive electric air blower types or a well designed septic tank.

Return on Investment.

For building owners with apartment blocks in Nairobi suburbs such as Rongai, Ruai, Ruiru where the rent charged is not enough to offset the daily running costs of the air blower type of biodigester, the septic tank becomes the best option since it works just as well and costs 90% cheaper.

This running cost can be compared in a way with a swimming pool running cost. After construction of a swimming pool, the maintenance costs for technical human resource persons, electricity and chemicals can hit an average of kes 20000 to 30000 per month.

The air type biodigestors also require technical persons, electricity and chemicals , albeit on a much lower scale than a swimming pool.

History of Septic tanks in Kenya.

The intial septic tanks constructed in Kenya by the colonial government in the 1940s,50,60s and 70s work perfectly well till todate.

They were small in size and all detailed specifications on how septic tanks should be constructed were put in place.

Septic tanks constructed in the 90s, 2000s to currently lost out on details, with building owners having unqualified personnel constructing the septic tanks, leading to an unnecessary high cost of construction and high failure rate for the same, leading to the current biodigester boom to give a solution to waster water disposal. The poor specifications have resulted in high financial losses , which can be resolved by having the septic tank constructed to the required specifications.

Sizing of septic tanks.

Septic tanks are sized by the number of occupants they serve.

2 Bedroomed House septic tank size.

A 2 bedroomed house, with 4 people living in it will have an outflow of 200 liters of water per day. This should have a septic tank of 1m width by 1.5m long by 1.5meters deep.

20 unit apartment block septic tank size.

Similarly, for an apartment block of 20 units, each with 3 people living inside, will have an outflow of 2400 liters of water daily and will require a tank size of 1.2meters wide by 2meters long by 1.5meters deep.

These sizes are small and cost far much less than the biodigestors.

When septic tanks are constructed without the calculated dimensions, they will be too large, hence expensive to build, and the large size that is not commensurate to the number of users will make the internal conditions that aid the anaerobic decay not to work properly, leading to the tank getting full too fast or blocking altogether.

Grease traps.

Well designed septic tanks will require grease traps at the entry point and exit point into the soak pit to prevent the grease from kitchen water clogging the soakpit pipes , preventing the soakage, which results in backflow buildup failure.

A grease trap costs kes than kes 1,000 to construct, but when not put in place, can result in frequent septic tank exhaustion costs or re constructing the soak pit all over again.

Partitioning.

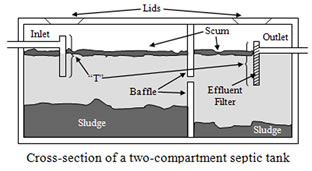

Septic tanks need an internal partitioning with the 1st chamber 2 times the size of the 2nd chamber, with the inlet into the second chamber located lower than half the height to prevent non bio degradable waste from blocking the outlet.

A sufficient height versus surface area, tending towards deepness is better in ensuring the biodegrading of the waster into soak-able liquid onto the soak pit.

Well placed vents at the last man holes will ensure that the foul smell will only be released very high up , ensuring the septic tank does not release any odor in the compound.

Architect Francis Gichuhi Kamau

info@a4architect.com

0721410684

Leave a Reply